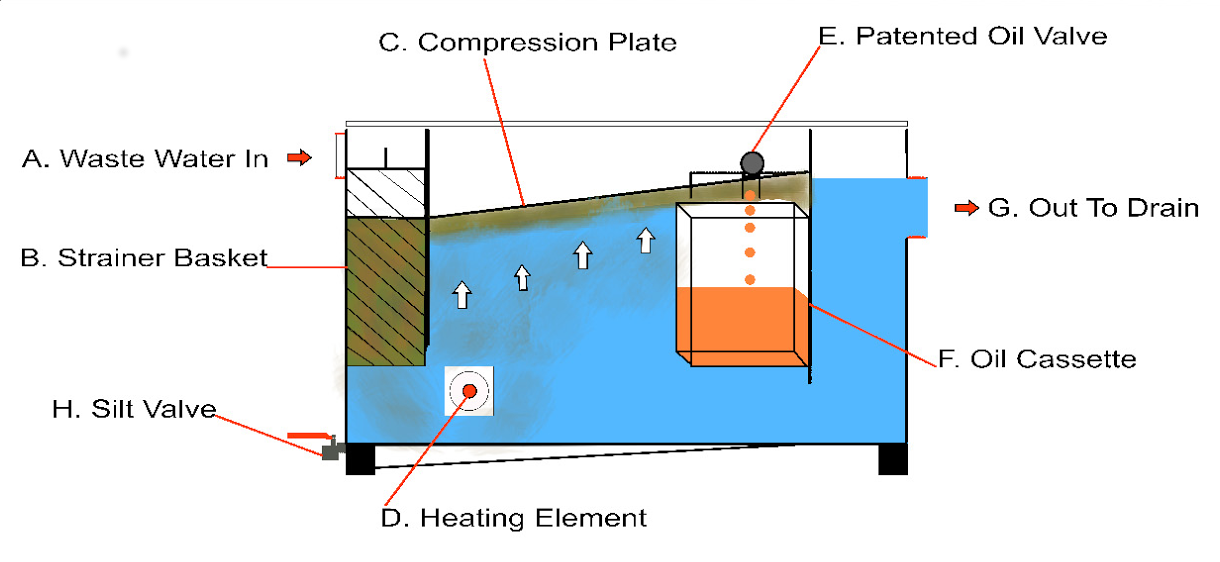

HOW THE FATSTRIPPA GREASE TRAPS WORKS

What happens inside grease trap

(A) Grease trap Waste water contaminated with F.O.G (fats, oils and grease) flows in through the inlet of the Fatstrippa Grease Traps.

(B) Small food particals are trapped in the stainless steel basket as the water passes under the first weir into the seperation chamber.

(C) The F.O.G rises up to the compression plate as it is lighter than water.

(D) The heating element helps the oil to seperate from the fine particals and rise up.

The compression Plate

(E) Because the compression plate is angled up, this will encourage the oil to travel up to the patented oil valve . This oil valve only allows oil to pass through and will close when it detects water.

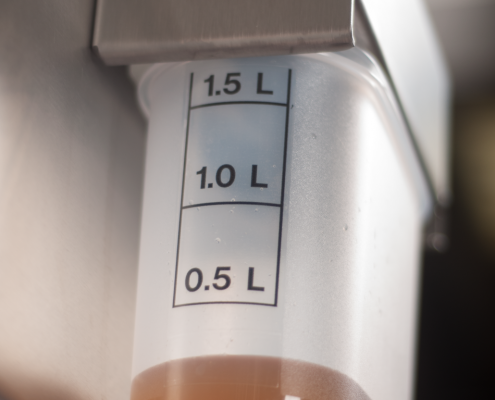

(F) The oil then passes into an oil cassette, which can be stored for collection by an oil supplier. This is a continuous, automatic and non mechanical process.

(G) The oil that is recovered is 99.6% pure. The water is now free of F.O.G content and leaves the unit through outlet G entering the drains without threat of blockage, and more importantly, compilant.

WHY CHOOSE FATSTRIPPA

Fatstrippa is by far the leading Automatic grease Recovery unit(grease trap) on the market today in Ireland and the UK.There are a number of reasons for this but the main reason is cost.While the original outlay is similar to that of its competitors , the real cost can be observed as time goes by.

No 3 monthly Service required

The Fatstrippa is not required to be services/cleaned out every 3 months by a certified company so the end user saves year on year with this cost.There are no moving parts on the Fatstrippa grease trap as it works on physics alone so no mechanical breakdowns again saving money and precious production time. There is no contract needed with the Fatstrippa grease trap.

Or follow us on Facebook or Twitter